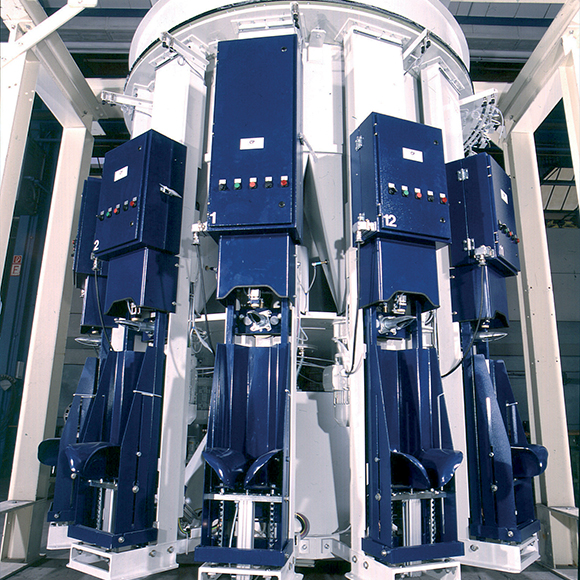

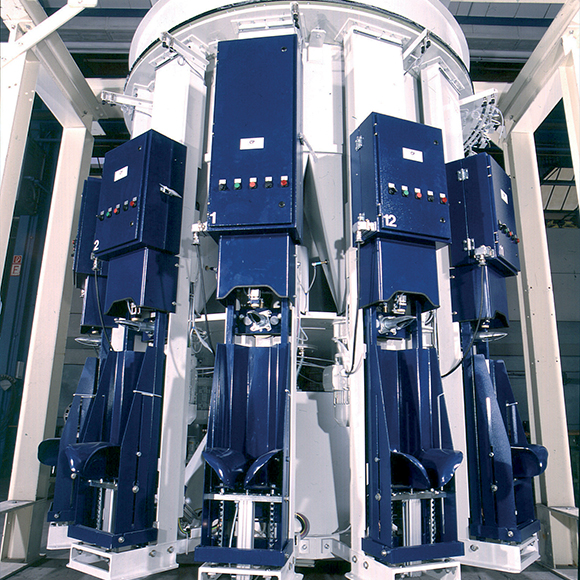

Rotary Gate

The Claudius Peters rotary gate is installed in vertical falling routes of pneumatic conveying systems to guide and control the mass flow.

The rotary gate consists of a cylindrical housing. Sealing of one outlet each is carried out by an adjustable gate. By turning the drive shaft, the gate shifts from one material outlet to the other. A flexible sealing, which is pressed against the housing wall by a compression spring, provides a dust-tight sealing of the locked outlet. The drive can be pneumatic, motoric or manual and is flanged directly to the rotating shaft, resulting in the highest safety possible by omitting the rods. The drives are designed with sufficient reserves so that even under aggravated conditions a safe operation is ensured.

Techniks

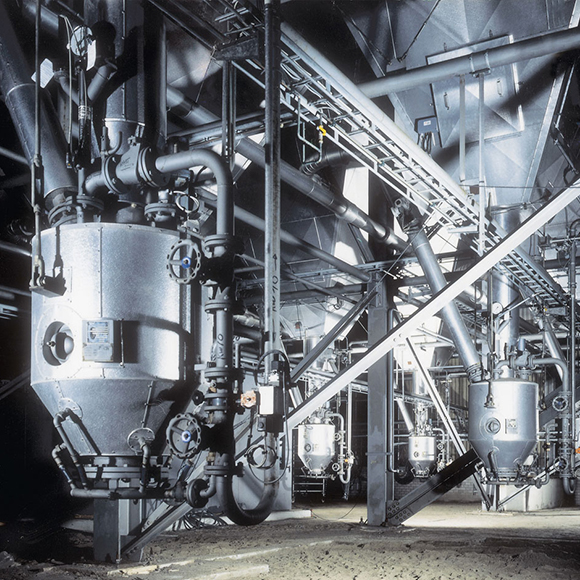

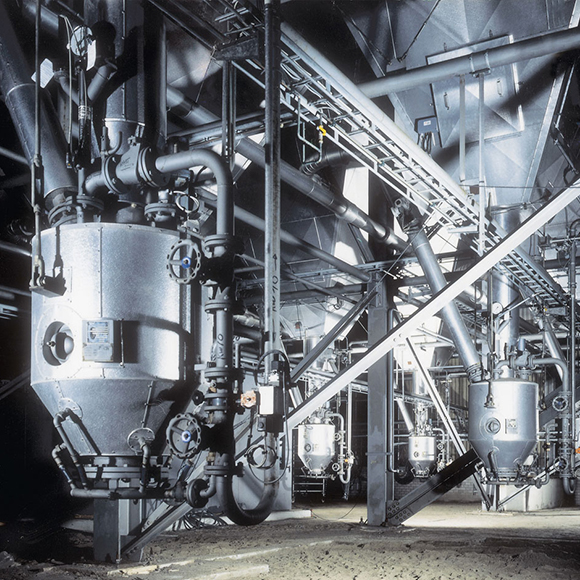

Ash Handling

When discussing the energy sources available for the generation of power in addition to gas and oil, the combustion of coal still plays a major role.

Calcining Technology

Claudius Peters can be your full line supplier for your gypsum processing system.

Clinker Cooling

When producing cement, the clinker cooler plays a decisive role downstream of the clinker production pyro process.

Dry Mortar & Mixing

Claudius Peters (CP) is a leading partner for the cement and building materials industry worldwide. Our vast product range is tailor-designed to meet the individual demands of every client, providing a complete solution.

Mineral Grinding Technology

Claudius Peters is widely acknowledged as one of the foremost authorities on coal and mineral grinding technology.

Packing and Palletizing

A large part of the most powerful packers and palletizers in use worldwide today come from Claudius Peters.