Clinker Cooling

Clinker Cooling: A Journey Through Innovation

When producing cement, the clinker cooler plays a decisive role downstream of the clinker production pyro process. A maximum of the amount of heat extracted from the clinker during the cooling process should be retained in the overall process – represented by the Cooler Efficiency.

Claudius Peters Clinker Coolers achieve the highest Cooler Efficiencies with simultaneous high availability and long service lives.

Claudius Peters supplies new clinker coolers, modifications sets and cooler components for all types of coolers.

Today, we are pleased to announce the arrival of Eta Cooler 5.0, the latest iteration of our acclaimed Eta Cooler series.

Claudius Peters Clinker Cooling Technology

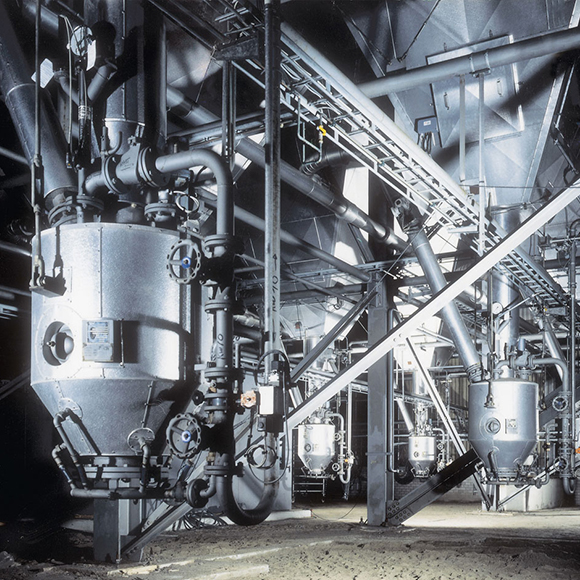

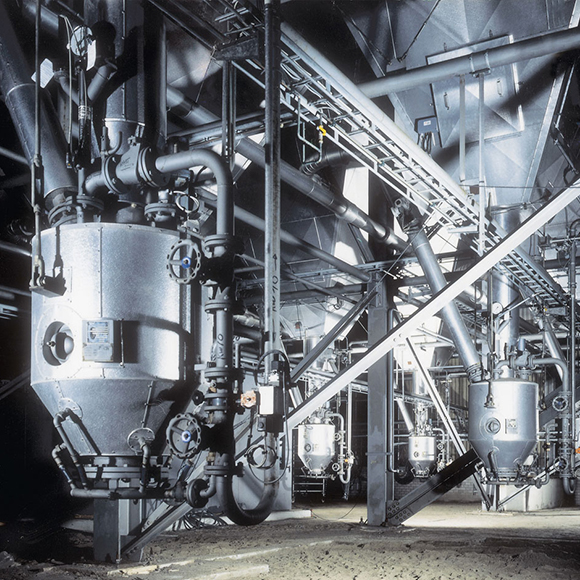

With over 800 clinker coolers commissioned around the world, Claudius Peters represents a leading role in the clinker cooling technology. Starting in the 1950’s, Claudius Peters has gained almost 70 years of experience and has been responsible for many of the innovative milestones reached in the past decades that are considered today as state of the art in the cement industry.

Older clinker coolers with one or more inclined grates or even newer coolers do not provide the efficiency and operating conditions possible today. Claudius Peters can show you a comparative calculation of the operating conditions possible today.

Contact us today so we can show you what savings and ROI you can achieve with a new state-of-the-art clinker cooler. Many projects from the past and today have shown that replacing the old clinker cooler with a modern Eta-Cooler pays off very quickly.

- 241

HE Module installed since 1994

- 280

Cooler conversions

- 852

Cooler since 1950

Claudius Peters Clinker Cooler - Eta Cooler

After 50 years experience in conventional grate coolers Claudius Peters continues to develop latest generation clinker coolers to excel over and above the features of older clinker cooler technologies. Worldwide it is considered to be the most technically advanced clinker cooler available today.

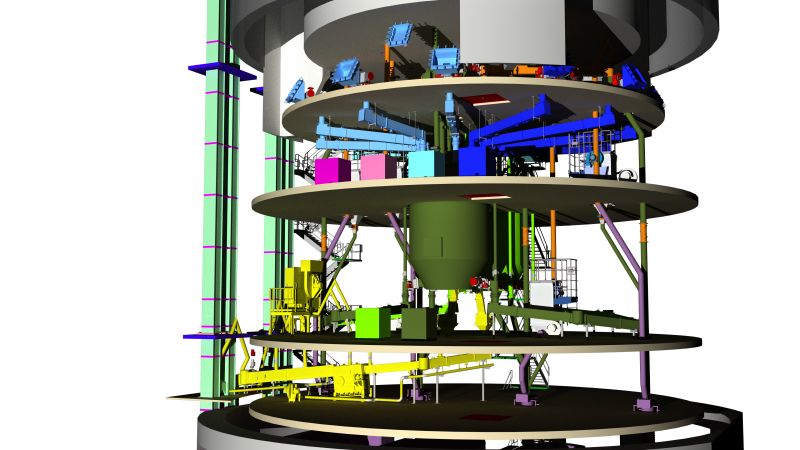

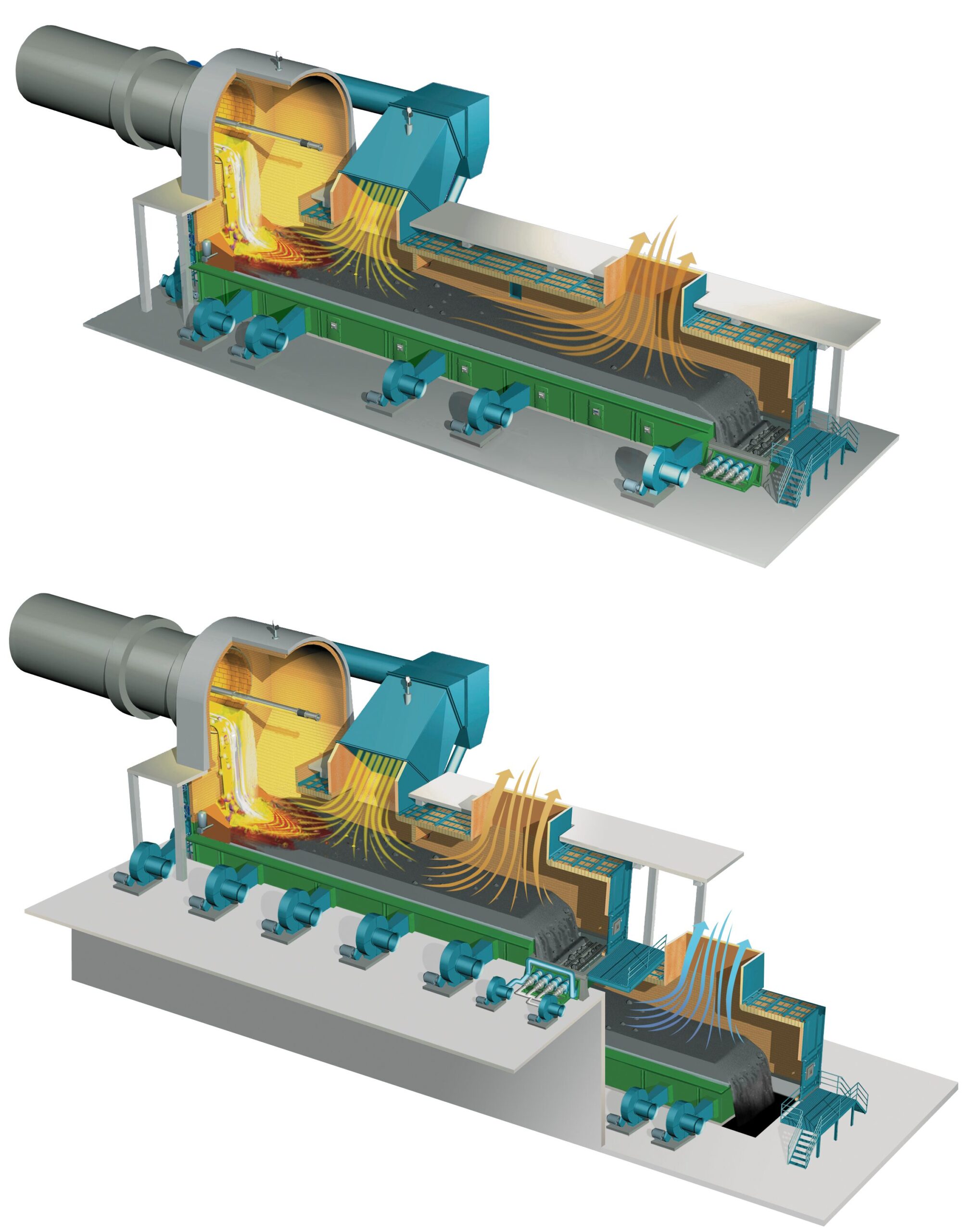

The Eta cooler consists of an HE-module (static inlet) in the kiln drop zone and standard units with horizontal arranged lanes, and enables operation with a higher clinker bed than conventional clinker coolers. This improves the function of the heat exchanger and generates a significantly higher degree of efficiency than with conventional grate coolers and beam coolers.

Claudius Peters offers

Flat Coolers – with the Hammer/Roller Crusher (at the end section)

Stage Coolers – with intermediate Roller Crusher

The compact design is a perfect fit perfectly for both Greenfield projects as well as cooler replacements for wet and dry kiln systems. The Eta cooler is particularly suitable for the use of Waste Heat Recovery(WHR-) systems and recirculation (i.e. Duotherm-) Systems. Owing to a high degree of efficiency, and the associated high and stable recuperation temperature due to the high clinker bed, the ETA cooler is particularly suitable for the sustainable use of alternative fuels (secondary fuels) and supports an increasing replacement of primary energy sources.

Since 2004, Claudius Peters’ Eta clinker cooler technology has successfully been supplied worldwide to many leading cement producers.

Moving floor technology

Autogenous self-protection – no transport elements in hot clinker layer

No clinker riddling

Controlled side aeration

Independent lane movement

Clinker bed height of 950 – 1200 mm

Low cooling air demand

Outstanding long clinker retention time

Highest thermal efficiency / excellent heat recuperation

Lowest maintenance requirements

Highest availability

Lowest operation costs

Lifetime guarantee of 5 years (on aerated transport lanes, support rollers and HE-module grate plates)

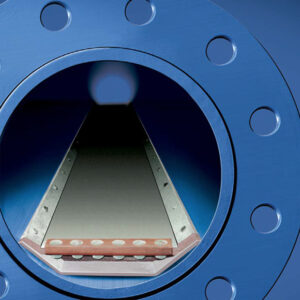

HE Module

Claudius Peters has supplied coolers for many years with a static grate in the inlet zone of the clinker cooler, the so-called HE module. In recent years, the HE module has been developed to achieve a long service life with low-pressure losses, reducing operating costs to a minimum.

Claudius Peters Clinker Crushers

The hammer crusher is the standard solution for crushing clinker. Claudius Peters has been supplying hammer crushers worldwide for capacities up to 6000 t/d since 1955.

Claudius Peters developed the roller crusher for use in clinker coolers at the end of the 1970s. Today, the roller crusher is the standard unit for crushing the clinker inside the clinker cooler. Due to the slow speed, the roller crusher produces a lower dust load and less wear inside the cooler and on the crusher itself.

Clinker Cooler Modifications

After 70 successful years in the clinker cooler business as a technologically leading company, Claudius Peters is the reliable partner for conversions and modifications.

We offer the complete range of services, from the replacement of individual plant components, the replacement of only the core parts, to the complete replacement of coolers.

In close coordination and cooperation with our customers, we develop the best possible solution for the respective application.

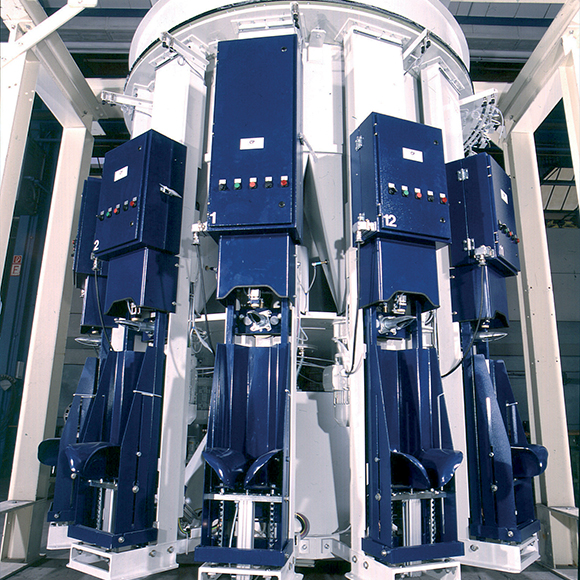

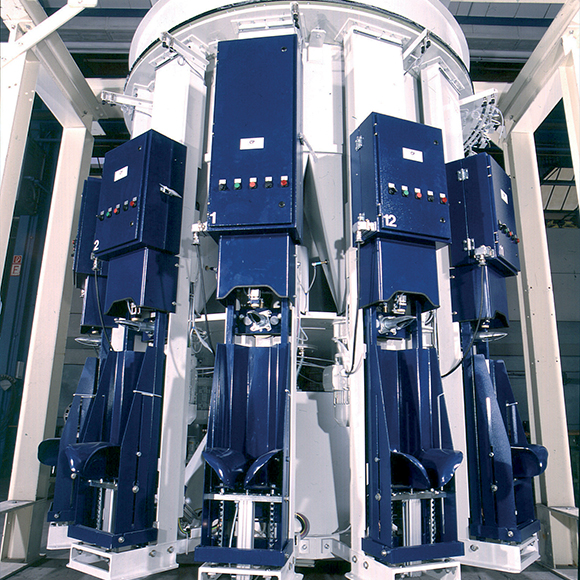

Grate Motion Control box (GMC)

The Grate Motion Control box (GMC) is a major part of the hydraulic grate drive of Claudius Peters clinker coolers. One GMC is used for each cooler grate. The GMC converts the master signal of the ‘clinker bed height’ control loop into a control signal, which changes the grate speed (number of strokes) via a hydraulic proportional valve. In addition, the GMC controls and monitors all the proportional valve functions as well as the grate motion.

Downloads

-

-

Customised Engineering and Clinker Cooling World Cement Article

-

Cooler Grate GMC Data Sheet

Related Techniks

Ash Handling

When discussing the energy sources available for the generation of power in addition to gas and oil, the combustion of coal still plays a major role.

Mineral Grinding Technology

Claudius Peters is widely acknowledged as one of the foremost authorities on coal and mineral grinding technology.

Calcining Technology

Claudius Peters can be your full line supplier for your gypsum processing system.

Clinker Cooling

When producing cement, the clinker cooler plays a decisive role downstream of the clinker production pyro process.

Packing and Palletizing

A large part of the most powerful packers and palletizers in use worldwide today come from Claudius Peters.

Pneumatic Conveying

As one of the world’s leading names in the supply of systems and equipment for the pneumatic transport of dry materials in large quantities, you would expect us to know a thing or two about innovation, and you would be right.

Silos Technology

Our groundbreaking technology is also prevalent in high capacity bulk storage and mixing silos.

Stockyard Technology

Claudius Peters expertise in stockyard materials handling has been gained in over a hundred installations worldwide across a wide range of bulk materials, capacities and configurations.