New! Eta Cooler 5.0

We are pleased to announce the arrival of Eta 5.0, the latest iteration of our acclaimed Eta Cooler series.

- Reduced energy consumption

- Less maintenance down-time

- Lower environmental impact

Eta 5.0 offers significant energy savings, lower maintenance down-time and reduced environmental impact.

Our engineers have achieved remarkable efficiency improvements by designing a new low-pressure-drop system and by reducing friction in the transport system, which also means less maintenance down-time.

Significantly, Eta 5.0 can be retrofitted to existing installations with minimal intervention.

The Claudius Peters Eta Cooler 5.0 represents the new benchmark of cooler technology and is the ideal solution for the demands of next-generation clinker production.

Support Services

In addition to developing and delivering our state-of-the-art Eta Cooler technology, we offer a comprehensive range of engineering services to ensure your clinker cooler consistently operates at peak performance. Our experienced engineers provide worldwide support with:

- Supervision of installation and commissioning of new Eta Cooler systems

- Technical troubleshooting during ongoing operations

- Performance evaluations, process optimisation and modernisation

- Customized after-sales support to maintain long-term system efficiency

From initial installation to retrofit projects, we support our customers throughout the entire lifecycle of their Eta Cooler ensuring maximum availability, energy efficiency and process stability.

- 241

HE Module installed since 1994

- 280

Cooler conversions

- 852

Cooler since 1950

Innovation in Design: The Smooth Surface Advantage

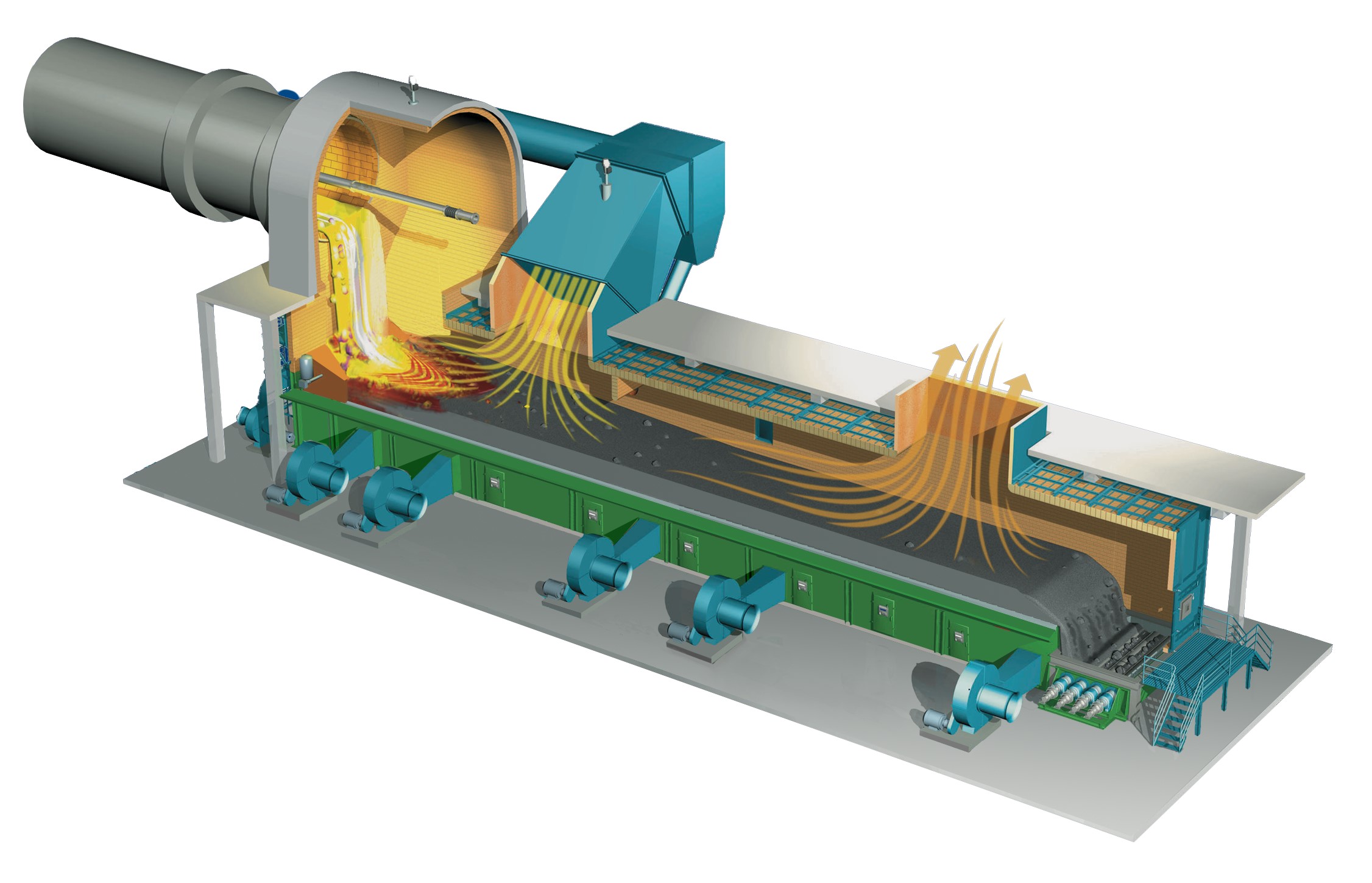

At the heart of the Eta Cooler 5.0 stands our well-proven moving floor design, reengineered with a smooth surface, eliminating traditional pockets for a protection layer. This streamlined design reduces shear forces during the backward stroke, minimizing clinker compaction. The result? Improved air flow and enhanced overall performance with a constantly low power consumption.

Key Features and Benefits

1. Optimised Cooling Airflow

- Reduced pressure drop across the clinker bed.

- This innovation minimizes energy consumption, enabling significant savings in electrical power.

2. 25% Less Energy

- Lower Fan Pressure and Reduced Drive Forces result in substantially and consistently lower electrical power requirements.

- Enhanced thermal efficiency, with optimal heat recovery – the maximum on the market – the trademark of the Eta Cooler since its market launch – will be retained.

3. Durability for the Long Haul

- A long-life concept ensures low wear with reduced moving cycles, no movement between grate plates, and lower moving floor temperatures achieved due to undisturbed clinker flow.

4. Clinker Transport Redefined

- The smooth-moving floor ensures slow, long transport strokes, with improved transport efficiency and support a high clinker bed for superior thermal performance.

- Reduced relative movement minimizes wear and clinker riddling, maintaining product integrity.