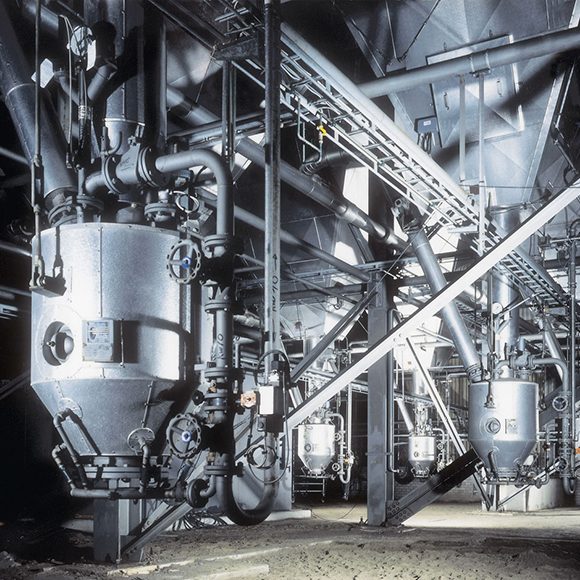

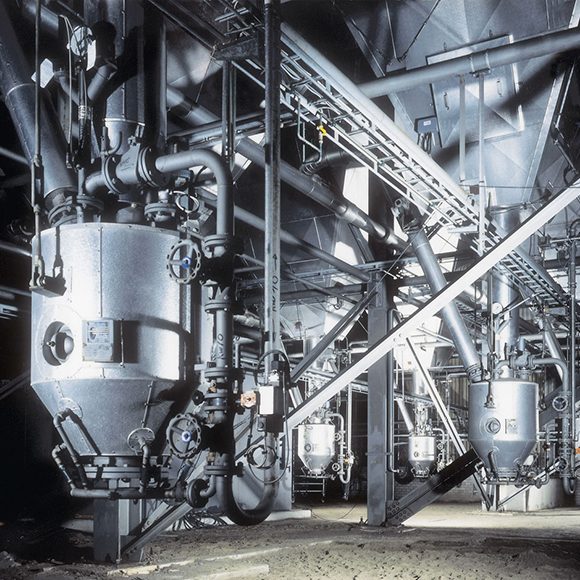

Pulverized Fuel Injection

Pulverized fuel injection or ‘PFI’ technology is just one area where Claudius Peters brings together several of its ‘Techniks’ to offer a comprehensive turnkey system.

Combining unparalleled knowledge of grinding and pneumatic conveying over long distances and silo storage expertise with precise measuring and coal dosing technology – PFI systems bring together several of Claudius Peters individual technologies to provide a comprehensive turnkey solution, which in the steel industry, has become a technology in its own right.

In this instance PFI technology is used in the steel making process to replace up to 50% of the coke charge used for smelting, with the far cheaper fuel, coal, offering a lower cost, more efficient and more environmentally friendly system.

- The first dense phase distributor system in 1984

- 52 pulverized coal injection systems for blast furnaces

- Coal injection systems with 15 million tons per year total capacity

- The world’s largest coal grinding and injection system with a today’s capacity of 320 t/h to ILVA, Taranto in Italy

Related Techniks

Ash Handling

When discussing the energy sources available for the generation of power in addition to gas and oil, the combustion of coal still plays a major role.

Clinker Coolers

When producing cement, the clinker cooler plays a decisive role downstream of the clinker production pyro process.

Calcining Technology

Claudius Peters can be your full line supplier for your gypsum processing system.